2022.05.06

Ocean Harvesting develops a new buoy made of high-strength concrete for its wave energy converter

Karlskrona/Gothenburg, Sweden; 6 May, 2022

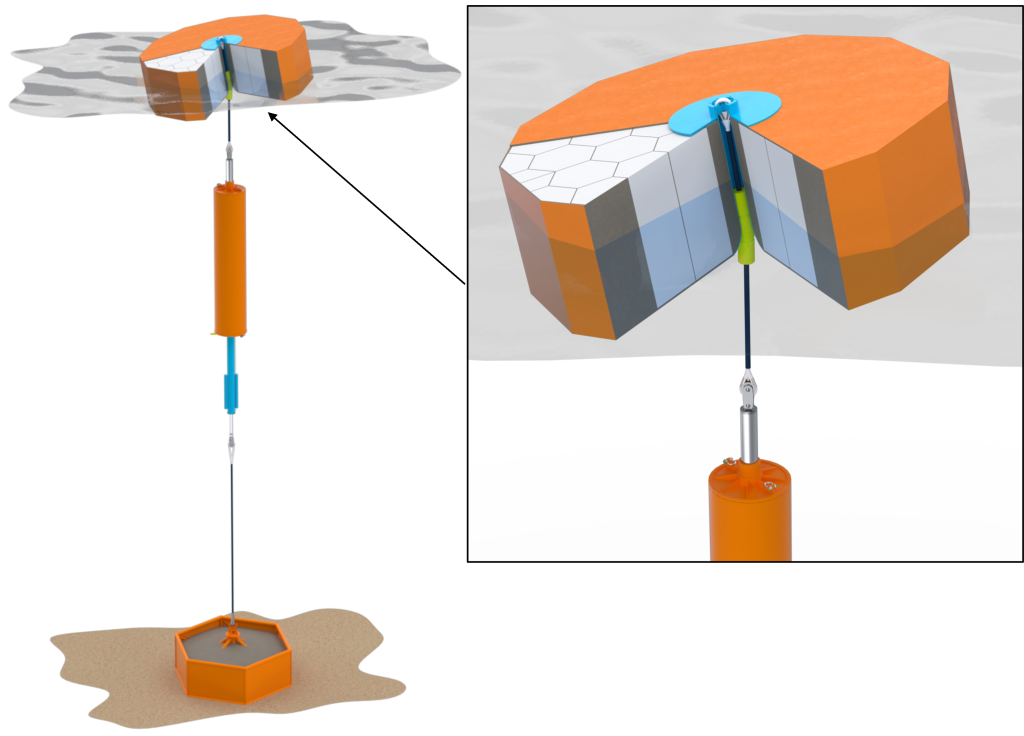

Ocean Harvesting is developing a novel concrete hull for the prime mover (buoy) of the InfinityWEC wave energy converter, using high strength concrete with low environmental footprint and excellent durability. The solution allows for large scale production and results in a buoy with a weight similar to a conventional steel hull, but at 1/4 of the cost and 1/3 of the CO2 footprint.

Highly flowable concrete is poured into a mould with void fillers, forming the concrete shell and the internal honeycomb structure, one of the strongest structures in nature. Most of the raw materials will be sourced locally at the installation site, where the buoy is cast in a process common in civil engineering. The buoy will be towed or shipped to the installation site and linked to the InfinityWEC PTO system with a mooring rope, which enables quick and diverless attachment and detachment of the buoy from the PTO system during installation and maintenance operations.

The RISE (Research Institutes of Sweden) department for Infrastructure and Concrete Technology has developed a unique high-performance concrete mix for the buoy, as part of the joint industry project WECHull. To facilitate a thin-walled, lightweight structure and easy, rapid manufacturing, alternative reinforcement measures were investigated, evaluating the use of fibres of different types (carbon, aramid, glass, steel and biomass), as well as polymer reinforcement with carbon-textile grids. By using recycled aggregates and replacing more than 50% of the cement content, InfinityWEC’s buoy is aligned with the European Circular Economy Action Plan.

The next development stage for Ocean Harvesting is a sea trial of InfinityWEC at scale 1:3, a project planned to start in November 2022. The sea trial will demonstrate the InfinityWEC technology and its control system, and their performance in the real sea environment. This is a critical step towards the final validation stage of the system at full scale and the commercialization of the technology.