Technology

InfinityWEC Solution

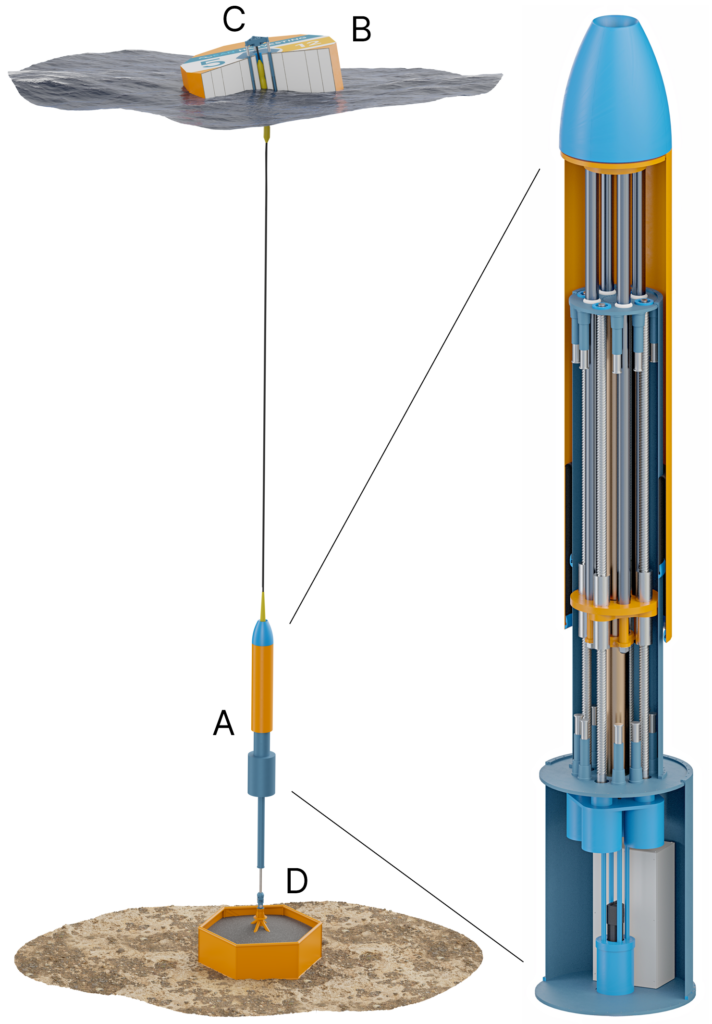

InfinityWEC is a 500 kW point absorbing wave energy converter with a highly efficient power take-off, capable of providing instant force control, to host advanced model-based predictive control strategies to maximize power output, reduce loads and improve lifetime and reliability.

A. PTO with Instant Force Control

A combination of ball screw actuators and a hydrostatic pre-tension system provides instant force control in the power take-off (PTO), enabling advanced control algorithms to increase energy output, reduce loads and improve reliability.

Ball screws convert linear motion and force into high speed rotatory input to direct drive generators/motors, providing high efficiency, high power density and high reliability.

The PTO hull is split in two halves, being pushed together by the surrounding water pressure close to the seabed. This way half of the PTO control force is provided “for free”, reducing cost and improving overall efficiency.

A level cylinder below the PTO adjusts the height for tidal variations, to maintain the same depth.

Optimal Force Control

Model Predictive Control (MPC) of the PTO force to maximize power output in every individual wave.

Depending on wave resource, the annual energy production is increased 25-50% compared with sea state tuned (non-predictive) reactive control.

B. Concrete Buoy

Buoy made as a honeycomb structure consisting of thin walls of high-performance concrete and EPS cores

Low cost, recyclable and commonly available raw materials

Onsite manufacturing, short production time and long life with low maintenance

C. End-stop Spring

Mooring rope attached to a damping system on top of the buoy, reducing the maximum loads during end-stops by half

Activated by the end-stops in the PTO, extending the relative motion of the buoy

Stiff connection to the PTO within the force control range, to maximize power capture performance

D. Easily Deployed Anchor

Concrete anchor cage, easily deployed and then filled with ballast through a down pipe from a transportation vessel

Manufactured on site

Short installation time

Low Cost

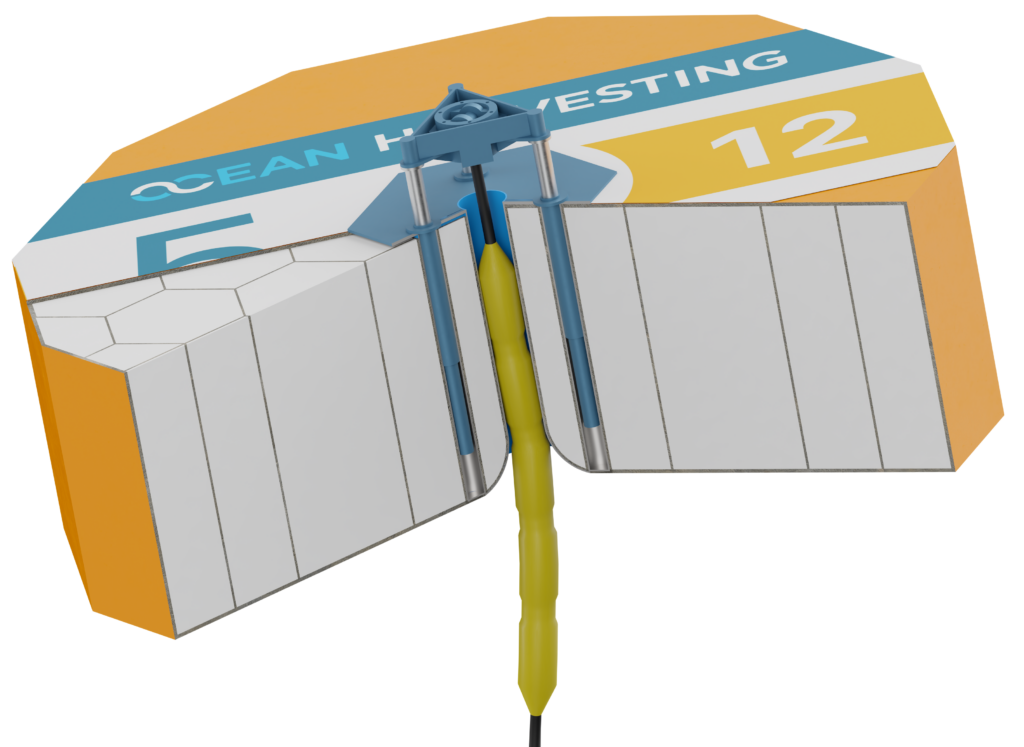

Concrete Bouy

Solid honeycomb structure with the outer shell and internal thin walls made of highly flowable high-performance concrete (HPC). A circular material with low carbon binder and recycled aggregate. EPS cores are used to form a mould and act as void filler to prevent water ingress. Low cost, corrosion resistant, recyclable and commonly available raw materials.

Compared to a buoy with steel hull, the concrete buoy has equal weight but four times lower cost, three times lower CO2 footprint and can be manufactured onsite ten times faster.

Read more about the WECHULL project.

Mooring rope attached to a damping system on top of the buoy, reducing the maximum end-stop loads by half.

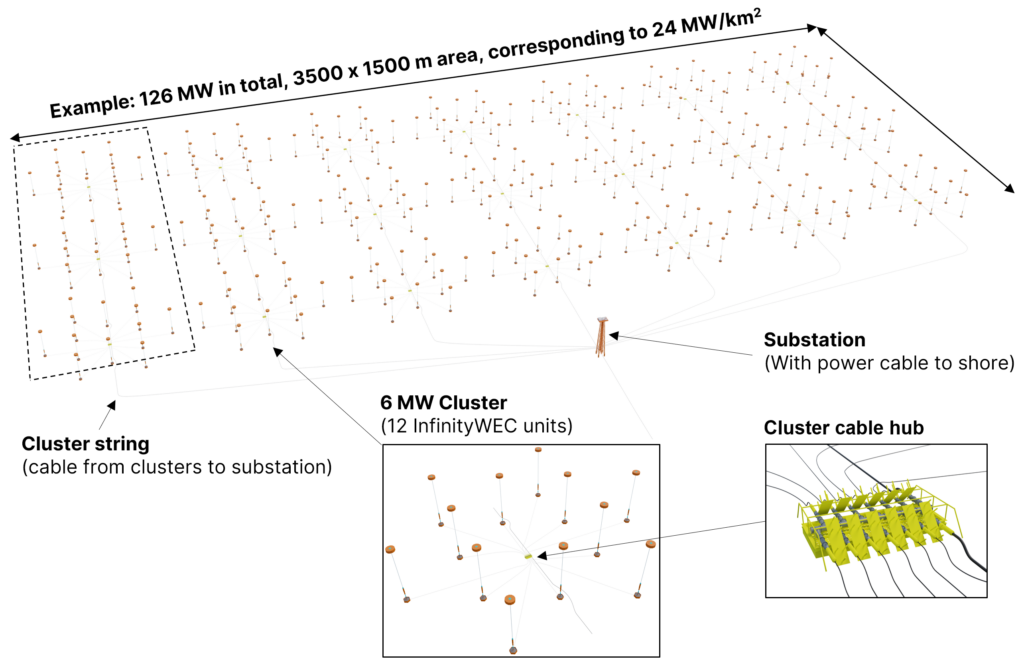

InfinityWEC Wave Farms

A wave farm consists of multiple InfinityWEC´s arranged in star shaped 6 MW clusters á 12 WEC units. This topology is area efficient, provides good access to all WEC´s for service vessels, and the total length of the power cables are relatively short. In the wave farm below, three cable hubs are connected on a string cable to a central substation for the wave farm, where power is transformed to higher voltage and exported. A total of 21 clusters arranged in seven strings provides a total power rating of 126 MW, with an electrical infrastructure very similar to an offshore wind farm.

The system is installable with a minimum of complicated offshore operations and no diving or heavy lifting are necessary offshore. An anchor cage is lowered to the seabed with a crane and filled with 500 ton high density ballast from an installation vessel. The 100 ton buoy and 40 ton PTO are towed separately to the installation site. The PTO is first connected to the power cable retrieved from the cable hub with ROV, then lowered in a vertical position and connected to the anchor. The buoy is finally connected by pulling the upper mooring rope from the PTO through the center of the buoy and locking it with a pin from the top.

Road Map

OHT aims to become a leading supplier of wave energy converter technology to project developers and power companies, contributing to the renewable energy transition.

The wave energy converter InfinityWEC is developed in a staged approach in line with Ocean Energy Systems framework for ocean energy technology. Read more

Next is stage 3, Scaled Demonstration in a sea trial project Q2 2024 – Q4 2026. The scaled demonstration will be followed by full-scale demonstration, arrays demonstration and commercialization.

OHT participates in several joint industrial projects financed by Swedish Energy Agency, EU’s Clean Energy Transition Program (CET-P) and Horizon Europe. These projects involve a wide range of partners in the value chain, such as suppliers, universities, research institutions, technology developers and power companies.