Ocean Harvesting and ball screw manufacturer NSK have completed the design of the ball screw actuation system for InfinityWEC generation 6, and Ocean Harvesting is now raising 500 000 EUR for 2024 activities and preparing for a 1:3 scale sea trial project in 2025-2026.

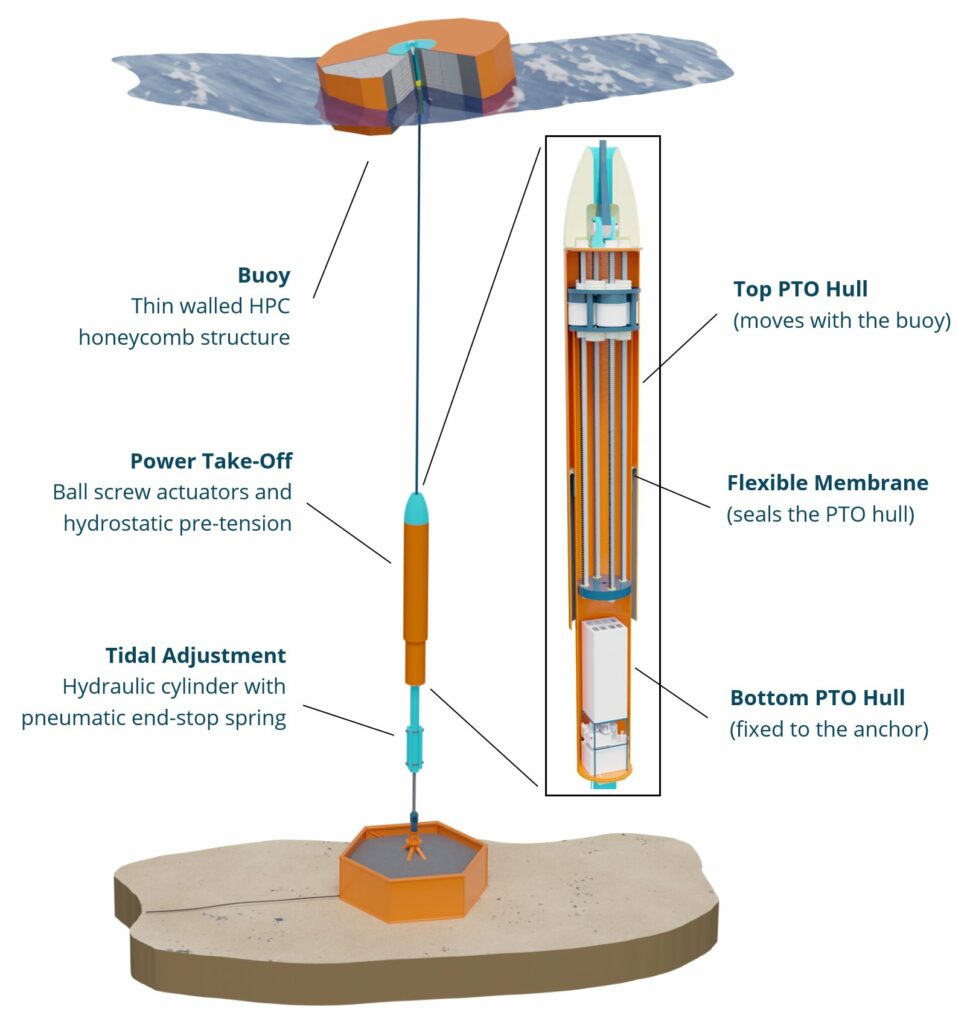

Wave energy is a vast resource of renewable energy that can produce electricity more consistently and at different times than wind and solar. This increases the value of produced electricity and reduces the energy storage needed to balance the grid. InfinityWEC is a novel wave energy converter with a breakthrough power take-off and control system, providing an outstanding annual energy production by maximizing the energy output from every individual wave. The technology also has very high material efficiency using circular materials with low-cost and low-CO2 emissions, leading to low cost of electricity and low environmental impact.

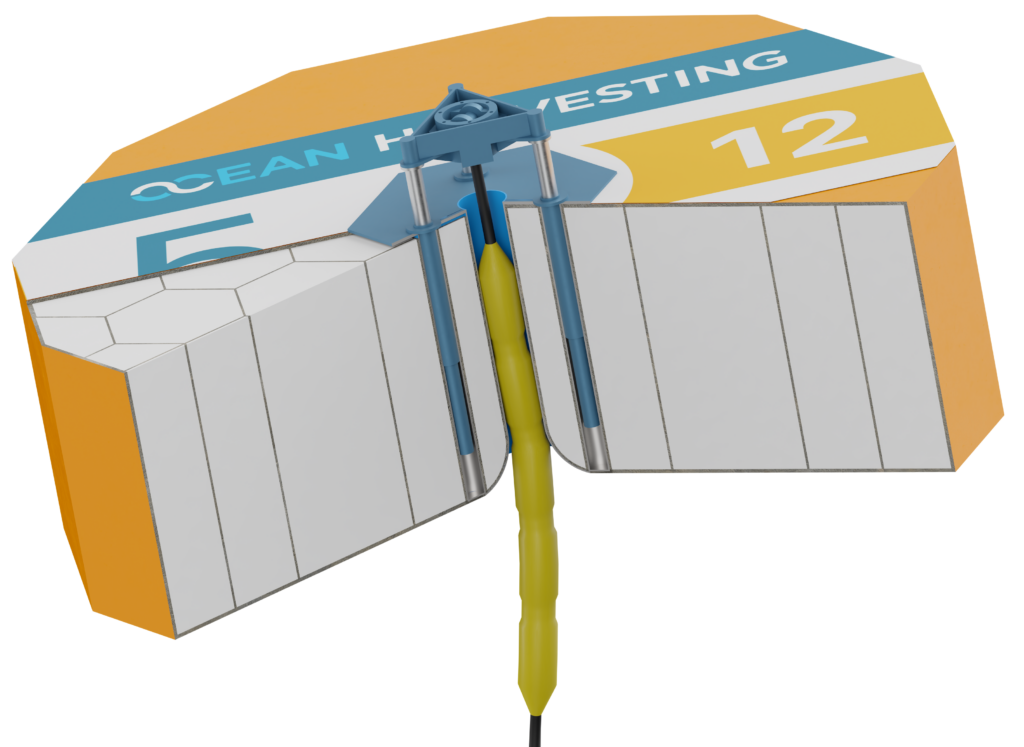

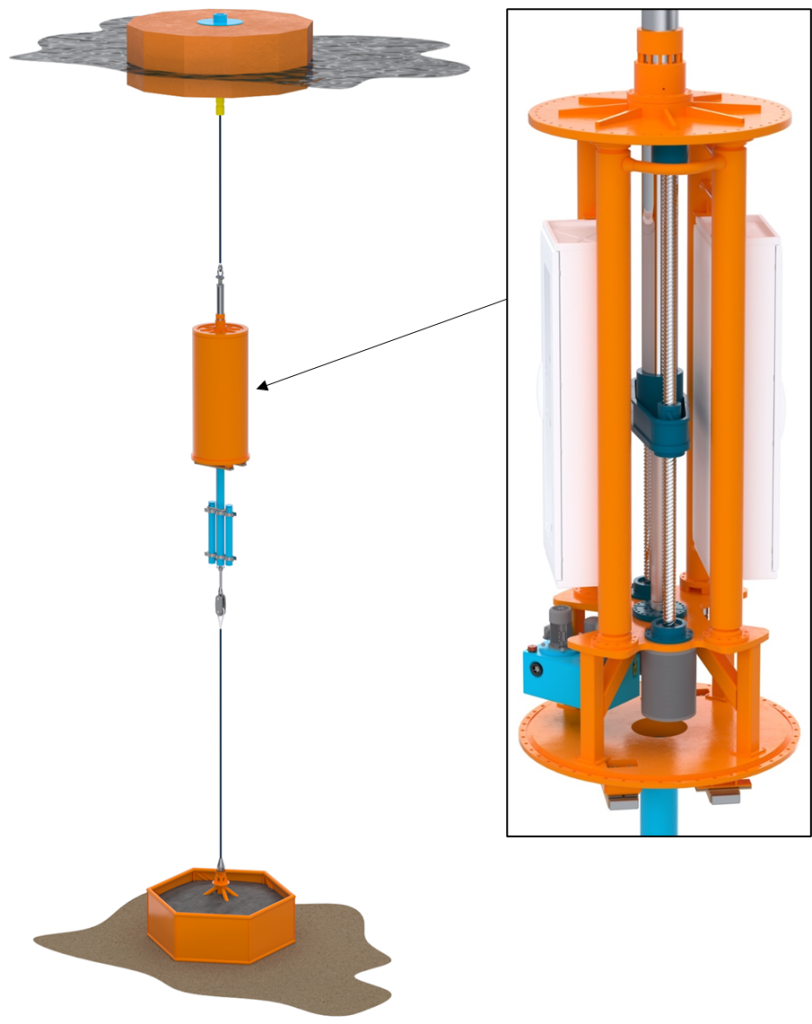

During 2023 and early 2024, Ocean Harvesting has focused on developing the ball screw actuation system in the generation 6 power take-off of the InfinityWEC wave energy converter. Simulation models have also been updated and extreme and fatigue loads have been analysed.

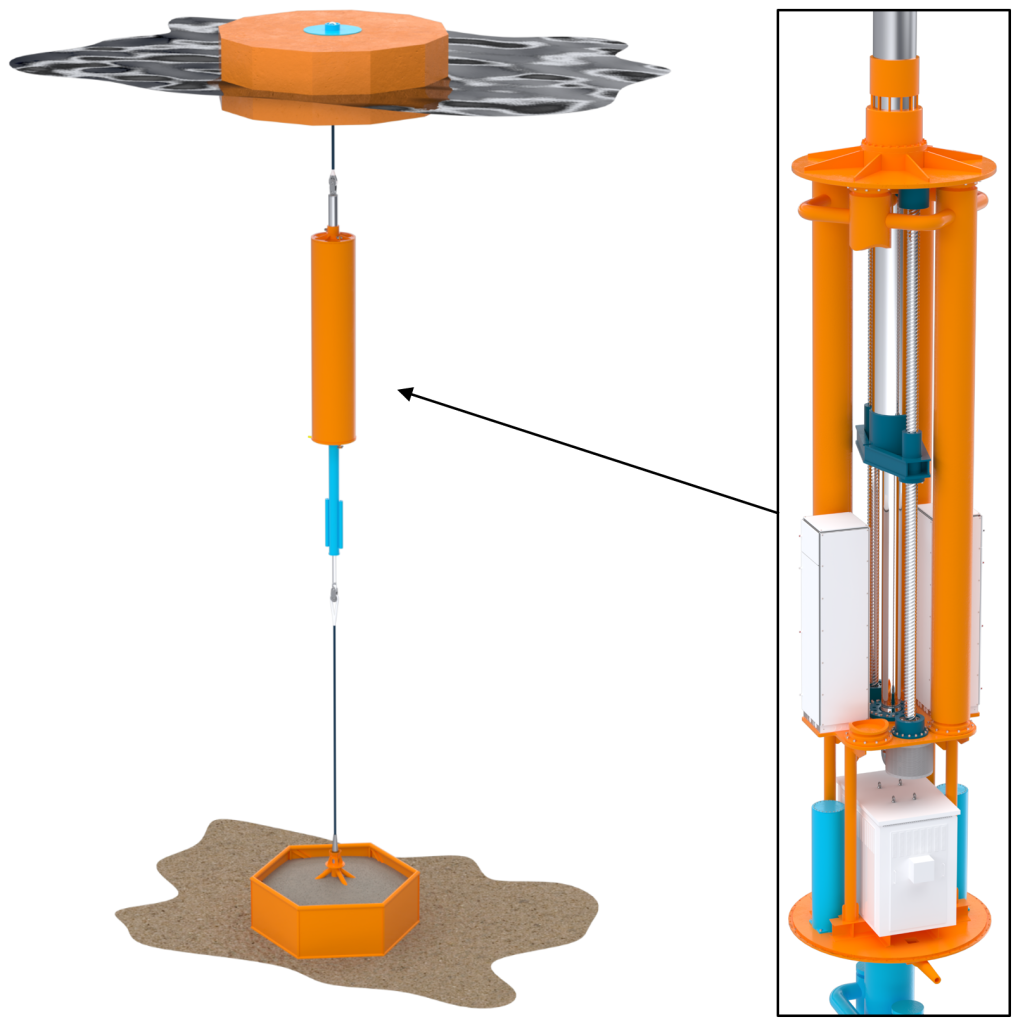

Ball screws are very efficient at converting linear motion with high force into a high-speed rotation suitable for direct drive generators/motors, to provide instant force control which is key to InfinityWEC’s exceptional energy production performance. InfinityWEC is a novel and challenging application with regards to extreme and fatigue loads, and much work has been done to improve operating conditions for the ball screws. Furthermore, the number of ball screws in the PTO have been increased from two to four to achieve 25-year lifetime, which at the same time increases the available force from the ball screws from 1 to 2 MN. This in turn makes it possible to control the motion of the buoy and the velocity in the power take-off, which is important for the durability of the ball screws and to reduce forces during end stops.

“Ball screw actuators in combination with our hydrostatic pre-tension system is a very efficient solution,” says Mikael Sidenmark, CEO Ocean Harvesting, “which benefits from advanced predictive control algorithms to optimize the force applied to the buoy in every given moment, resulting in both outstanding annual energy production and that motion and loads can be controlled and reduced.”

Eduardo Rodriguez, Director NSK Europe, says: “We see a clear synergy between high efficiency products and limitless energy sources like waves, as well as many opportunities for success and development in this area. We’ve established a longstanding partnership with Ocean Harvesting, and know that together we can develop successful prototypes and deliver very promising results. NSK is a leading manufacturer of ball screws in the high-load sector, and we expect that developments like this will open up a large field of activity for us going forward.”

Mikael Sidenmark continues: “Focus in 2024 is to perform structural analysis, implement model predictive control (MPC), and to complete the full-scale system design. We will also prepare for a 1:3 scale sea trial project planned for 2025-2026, as well as bring forward our buoy technology as part of the on-going EU-financed WECHull+ project. For these activities in 2024, we are now raising 500,000 Euro, preliminarily divided into a 120,000 Euro financing for the period March – June 2024 and 380,000 Euro for the remainder of the year.”

For more information, contact:

CEO Mikael Sidenmark, +46 709 55 61 66

mikael.sidenmark@oceanharvesting.com

About NSK Europe

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 29,882 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2022, the more than 4,030 employees of NSK Europe Ltd. generated sales of over € 893 million.

www.nskeurope.com

About Ocean Harvesting and InfinityWEC

Ocean Harvesting is a privately held company based in Karlskrona and Gothenburg, Sweden. The development of the wave energy converter InfinityWEC was started in 2017.

InfinityWEC is a highly competitive and resource efficient technology with an advanced power take-off system using a combination of ball screw actuators and a hydrostatic pre-tension system to provide instant control if the force applied on the buoy. The solution benefits from the high performance achieved with model predictive control, resulting in outstanding annual energy production at the same time as motion and loads can be controlled and limited.

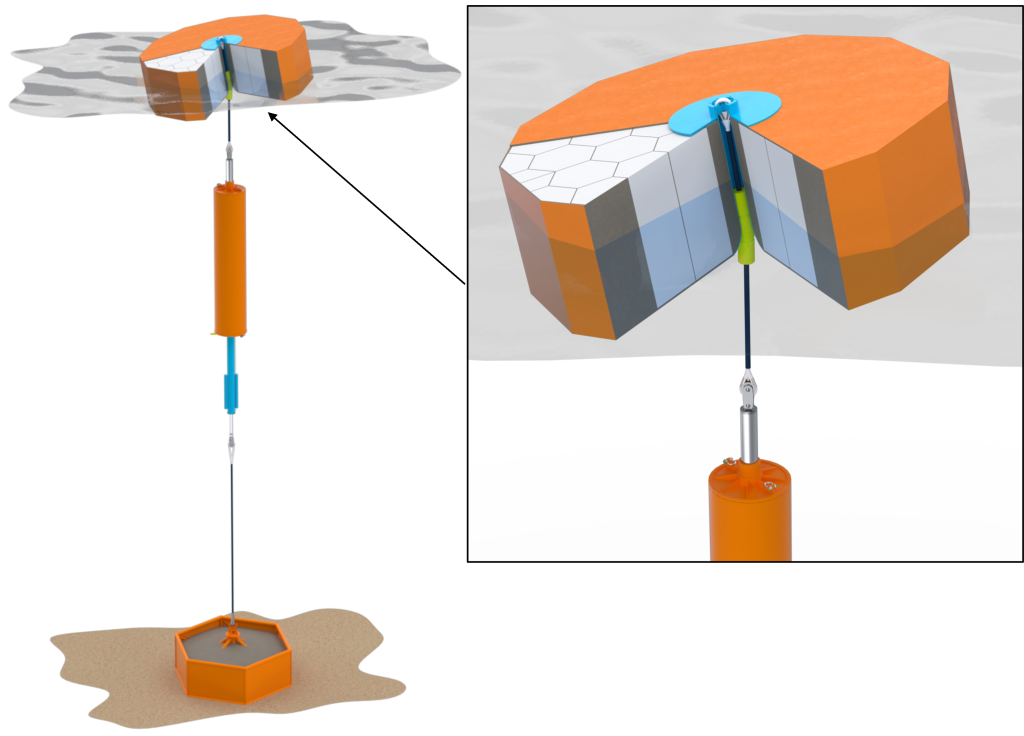

InfinityWEC is engineered for large-scale production and effective logistics with a power take-off that can be shipped with standard container transportation on road, railway and sea, and with a prime mover (buoy) made as a honeycomb structure with thin walls of high-performance concrete, that is casted with locally sourced materials at the installation site. A special high strength and sustainable concrete mix has been developed in collaboration with RISE Research Institutes of Sweden, enabling a prime mover with equivalent weight to a conventional steel hull, but at a fraction of the cost and manufacturing time.

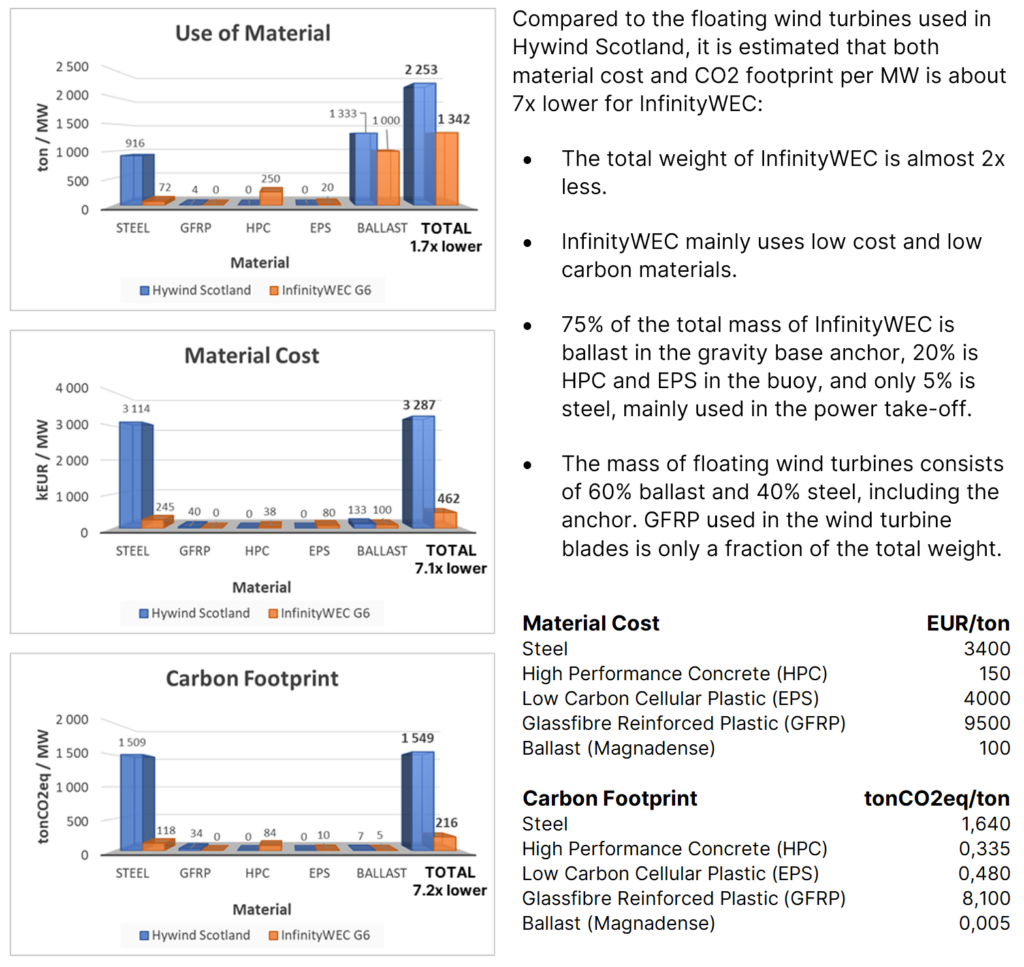

Compared to floating wind power, InfinityWEC uses only about half of the total amount of material and 90% of the used materials is low cost and low carbon concrete and ballast compared to almost only steel in a wind turbine, resulting in 6x lower cost and 6x lower CO2 footprint from materials used per MW installed capacity.

240307 OHT news – Update on InfinityWEC ball screw actuation system – en

240307 OHT news – Update on InfinityWEC ball screw actuation system – sv